Waa maxay qallafsanaantu?

Waa maxay qallafsanaantu?

Adkeynta Induction waa hab deminta adeegsada mabda'a soo-saarka korantada si ay u gooyaan xadhkaha magnetic field-ka beddelka ee beerta birta oo ay dhaliso qulqulka qulqulka dusha qaybaha birta. Marka loo eego saamaynta maqaarka ee hadda beddelka ah, dusha sare ee qaybta kulaylku si degdeg ah ayaa loo kululeeyaa qaabka qulqulka qulqulka ka dibna kicinta degdegga ah.

ka dib markii ay mashiinka kuleylka dhalinta dhammeeyaa habka kuleylinta iyo deminta, qaybaha birta ah ee adkaanta dusha sare waa mid sarreeya, xudunta udubdhexaadka ah waxay ilaalisaa caagagga wanaagsan iyo adkaanta, oo muujinaysa dareenka hooseeya, sidaas darteed saameynta adagaanta, xoogga daalka, iyo xirashada caabbinta si weyn ayaa loo hagaajiyaa. Sababtoo ah wakhtiga kuleylka gaaban, oksaydhka dusha sare, iyo decarburization ee qaybo ka yar, marka la barbardhigo daaweynta kulaylka kale, heerka diidmada qaybaha waa mid aad u hooseeya. Sidoo kale doorashada gariiradda kuleyliyaha induction ee ku habboon waxay door muhiim ah ka ciyaartaa daawaynta kulaylka induction birta.

Waa maxay sababta loo isticmaalo habka qallafsanaanta?

Deminta induction waa habsocod ay qulqulka qulqulka ah ay ka abuurmaan birta shaqada birta iyadoo la adeegsanayo koronto-magneeteedka oo qaybta shaqada la kululeeyo. Marka la barbar dhigo tignoolajiyada kululaynta birta ee caadiga ah, tignoolajiyada induction quenching waxay leedahay faa'iidooyinka soo socda:

1. Engegnaanta dusha birta workpiece waa sare. Adkeydka dusha sare ee qalabka shaqada ee lagu adkeeyey kuleyliyaha soo noqnoqda ee soo noqnoqda sare iyo midka dhexe waa 2 ~ 3 HRC ka sarreeya kan deminta caadiga ah. Saameynteeda birta adag tahay, xoogga daalka, iyo caabbinta xirashada ayaa si weyn loo hagaajiyay. Nolosha adeegga birta birta ah ayaa si weyn loogu kordhin karaa deminta induction.

2. Qalabka birta ah ee birta ah maaha kuleyl dhexdhexaad ah, markaa marka la adkeeyo induction, qaybta guud ee shaqada waa yar tahay;

3. Waqtiga kuleyliyaha birta workpiece waa gaaban yahay, qadarka decarburization oksidation dusha waa ka yar;

4. Ilaha kuleylku wuxuu ka shaqeeyaa dusha birta birta, xawaaraha kuleylka iyo waxtarka ayaa sarreeya;

5. Qaab dhismeedka qalabka deminta induction waa ka cufan marka loo eego qalabka kululaynta birta ee caadiga ah, fududahay in la shaqeeyo.

6. Mashiinka qallafsanaanta induction wuxuu garwaaqsadaa farsamaynta daaweynta kulaylka makaanaysan iyo si toos ah, badbaadinta qiimaha shaqada.

7. Tignoolajiyada qallafsanaanta induction ee adkaynta dusha sare waxa kale oo loo isticmaali karaa kulaylinta dhexgalka iyo daawaynta kulaylka kiimikada.

Sida loo doorto habka qallafsanaanta ee ku habboon?

Geedi socodka adkaanta induction waxa uu leeyahay dhowr habab kululaynta oo kulligood waxay leeyihiin workpieces kululaynta ku haboon.

1. Habka adkeeynta kuleyliyaha ee hal mar ah:

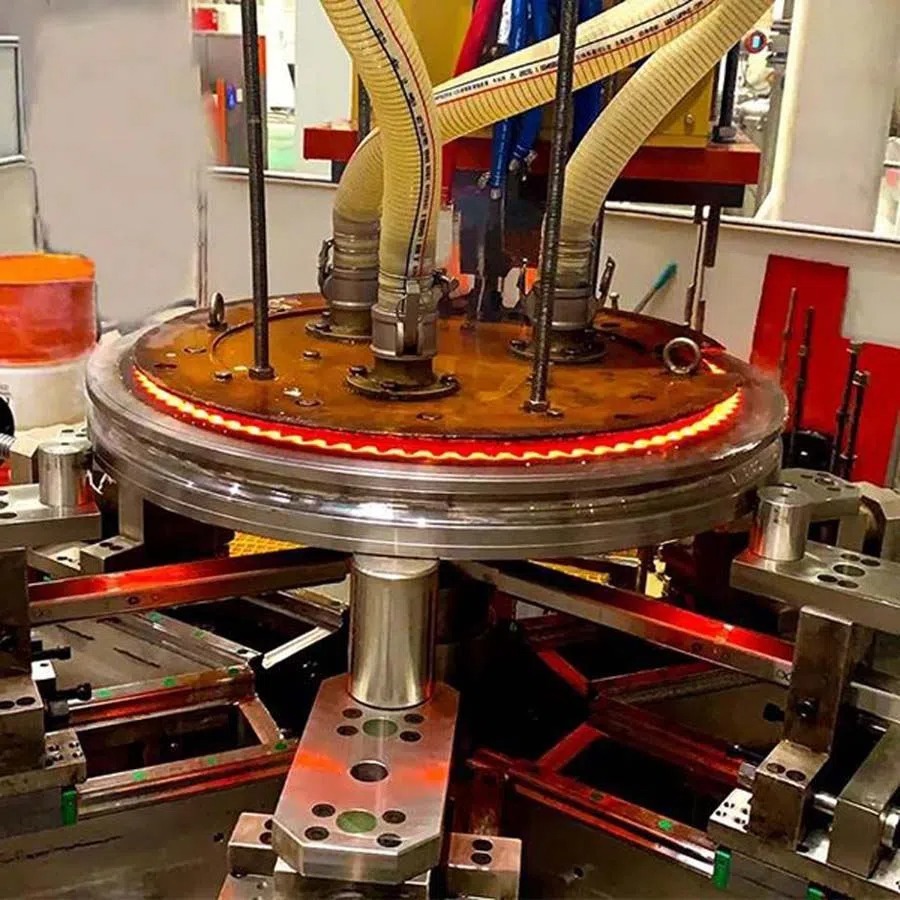

Kuleylka kicinta hal mar ah ama kuleylinta kicinta ee isku mar ah ayaa ah habka ugu badan ee adkeysigelinta kicinta. Marka habkan uu isticmaalo laba tuubbo oo leydi ah oo ku wareegsan dusha sare ee workpiece ee kuleylka wareega, waxaa caadi ahaan loo yaqaan Hal Shot.

Faa'iidada habkan kuleyliyaha induction waa in la dhammeeyo dhammaan aagga dusha sare ee shaqada kuleyliyaha shaqada hal mar. Sidaa darteed, hawlgalkeedu waa mid fudud, wax soo saarku waa sarreeyaa, waxay ku habboon tahay kuleylka aagga workpiece ma aha mid aad u weyn. Si aad u kululeyso qaybta shaqada ee weyn, raac habka kuleyliyaha ee hal mar ah, waxay u baahan tahay awood badan iyo kharash maalgashi oo sarreeya.

Tusaalooyinka ugu caansan ee kuleylinta kuleyliyaha hal mar ah ee hal mar ah waa gears modules yar iyo dhexdhexaad ah, baararka qolofka gambaleelka ee CVJ, dariiqyada orodka gudaha, taayirrada sideyaasha, taayirrada taageerada, biinanka guga caleenta, jiidiyaasha, darafyada waalka, fallaadho cudud ruxul, iwm.

2. Sawirka habka qallafsanaanta induction:

Marka aagga kuleyliyaha workpiece uu weyn yahay, sahayda kuleyliyaha induction waa yar yahay, habkan ayaa badanaa la isticmaalaa. Halkaa marka ay marayso, aagga kulaylka ee la xisaabiyay S waxa ay tilmaamaysaa gobolka uu ka kooban yahay giraanta induction. Sidaa darteed, cufnaanta awoodda isku mid ah, ah mashiinka kuleylka dhalinta awoodda loo baahan yahay waa yar tahay, tartanka Mashiinka adag ee induction Qiimaha maalgashigu waa yar yahay, ku habboon wax soo saarka qallafsanaanta dufcadda yar yar, tusaalooyinka caadiga ah waa usha piston-ka-ballaaran, duub duuban, duub, dhuumaha saliidda, usha suugada, tareenka, tareenada hagaha qalabka mashiinka iyo wixii la mid ah.

3. Qaybta hoose ee habka deminta kuleyliyaha hal-mar ah

Tusaalooyinka caadiga ah waa adkeynta induction camshafts badan, mar kasta oo kululeeyo hal ama in ka badan kamaradaha, ka dib marka ay dhammeeyaan wakhtigan induction quenching, kululaynta qayb kale oo kamarad ah, marshooyinku waa engegan yihiin ilig by ilig sidoo kale lagu dari karaa qaybtan.

4. Habka deminta iskaanka induction-ka-hoosaadka

Tusaalooyinka caadiga ah waa fallaadhaha ruxaya ama ulaha xawaaraha doorsooma ee induction qallafsanaan, halkaas oo qaybo badan oo ka mid ah usheeda lagu sawiray deminta induction, balladhka deminta laga yaabaa in ka duwan, iyo deminta iligga iskaanka iskaanka sidoo kale laga yaabaa in lagu daro qaybtan.

5. Kululaynta iyo ku deminta dareeraha

Deminta qallafsanaanta dareeraha, macnaheedu waa kobbinta induction oo dusha sare ee kuleyliyaha workpiece lagu rusheeyey dareeraha deminta induction, kuleyl, sababtoo ah cufnaanta awoodda dusha kululaynta oo ka weyn heerka qaboojinta dareere ku wareegsan. Sidaa darteed, dusha sare si dhakhso ah ayuu u kululaa. Marka inductor-ku uu damiyo, dusha sare ee shaqada ayaa adkaanaysa sababtoo ah nuugista kulaylka xudunta shaqada iyo qaboojinta dareeraha deminta.

Habkani guud ahaan wuxuu ku habboon yahay birta shaqada ee u baahan heer qaboojin yar oo muhiim ah. Marka qaybta shaqada la dhigo hawada oo gariiradda induction la damiyo, kulaylka dushiisa waxaa nuugaya xarunta shaqada. Marka heerka qaboojinta ee dusha sare ee kuleylka uu ka weyn yahay heerka qaboojinta muhiimka ah, qaybta shaqada waa la adkeynayaa, taas oo la mid ah deminta dareeraha.

Waa maxay qaybaha nidaamka qallafsanaanta induction?

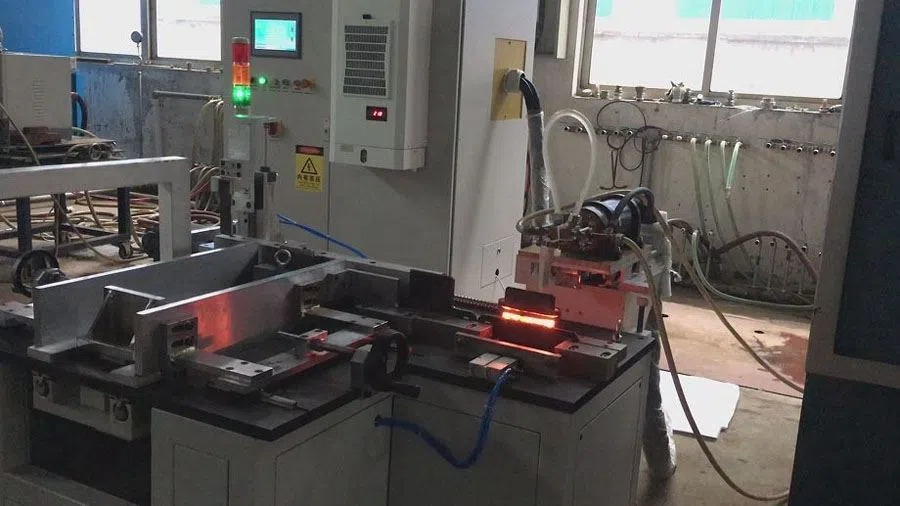

Halabuurka dhamaystiran Mashiinka deminta induction Guud ahaan waxaa ka mid ah koronto kuleyliyaha induction, qalabka mashiinka adkeynaya induction induction, gariiradda adkeynta induction, iyo nidaamka wareegga biyaha qaboojinta caawinta iyo deminta nidaamka wareegga dareeraha.

Soosaarayaasha qalabka kuleyliyaha induction casriga ah, qayb muhiim ah oo ka mid ah awoodda lagu fulinayo qalabyo dhammaystiran oo qalab adag induction iyo mashruuca furaha, isticmaaluhu si loo gaabiyo wareegga wax soo saarka, lagana fogaado sababtoo ah waaxyo badan oo sahayda ah ee habka wax-ka-saarku maaha mid iswaafaqsan. iyo xanuunada ciribtirka dheer sida waqtiga. Bixinta qalab dhamaystiran iyo mashaariicda furaha ayaa noqday hab lagu tartamo soosaarayaasha qalabka.

Wadar ahaan, Anagoo ah mid ka mid ah kuwa hormuudka ka ah soosaarayaasha nidaamka qallafsanaanta induction ee Shiinaha, waxaan ka caawinnay kumanaan warshado ah oo lagu daweeyo kulaylka si ay u helaan xalal daaweyn kuleyl ah oo ku habboon horeyba, si loo hubiyo in habka qallafsanaanta qallafsanaanta ee ku habboon habka deminta. Waxaad fadlan ii ogolaan kartaa in aan helo qaybahaaga qallafsanaanta sawirada, maaddada, qallafsanaanta, iyo adkaynta codsiyada qoto dheer, waxaanan ku siin karnaa habka kuleyliyaha induction ee la xidhiidha talooyinka farsamada ee ay weheliso xaashida xigashada. Mahadsanid.

Qallafsanaanta Deminta Nidaamka Qayb Kiisaska Codsiga ah

1. Raad-raac toosan oo qumman ee CNC nidaamka mashiinka deminta

2. Nidaamka qallafsanaanta silsiladda saxanka

3. Qalabka qallafsan ee CNC induction nidaamka mashiinka adag

4. Quenching Induction Bolt Power Dabaysha Khadka Wax Soo Saarka Nidaamka Heerkulka

5. Nidaamka adkaynta kuleylka daloolka gudaha ee qolofka dheellitiran oo dheellitiran

6. Adkeyn Large Mill Roller Induction